Car bumper molding is an essential component that offers both protection and aesthetic enhancement for vehicles. However, while it is widely used in the automotive industry, users often have concerns about its durability, installation, and overall effectiveness.

Durability and Material Concerns

One of the most common concerns about car bumper molding is its durability. Made from various materials such as plastic, rubber, or metal, the molding needs to withstand frequent impacts, weather conditions, and the rigors of daily driving. High-quality bumper molding is designed to resist scratches, dents, and fading caused by UV rays. However, cheaper alternatives may degrade over time, leading to cracks or discoloration. Users should opt for durable, UV-resistant materials to ensure the molding lasts longer and maintains its appearance.

Ease of Installation

Another concern is the installation process. Depending on the vehicle, bumper molding may need to be professionally installed, especially if it requires precise alignment or adjustments. While some aftermarket bumper moldings come with self-adhesive backing for easier installation, others may require drilling or special tools. To ensure a secure and accurate fit, it's important to follow manufacturer guidelines or hire a professional. Improper installation can lead to misalignment or moldings that become loose over time, reducing their effectiveness.

Aesthetic and Functional Value

Bumper molding serves two purposes: protection and aesthetic improvement. It helps protect the car's bumper from minor bumps, scratches, and low-speed collisions. Additionally, bumper moldings can enhance the vehicle's appearance, offering a sleek, stylish finish. For those looking to improve their car's look without undergoing major bodywork, bumper molding is an affordable and effective option. However, users should choose moldings that match the design of their car to avoid an overly bulky or mismatched appearance.

Car bumper molding is an important feature for both vehicle protection and enhancing aesthetic appeal. By selecting high-quality materials, ensuring proper installation, and choosing a design that complements the vehicle, users can maximize the benefits of bumper molding while addressing common concerns regarding durability and appearance.

https://www.bumpermould.net/product/bumper-mould/2020-for-skoda-kamiq-plastic-injection-front-bumper-mould.html

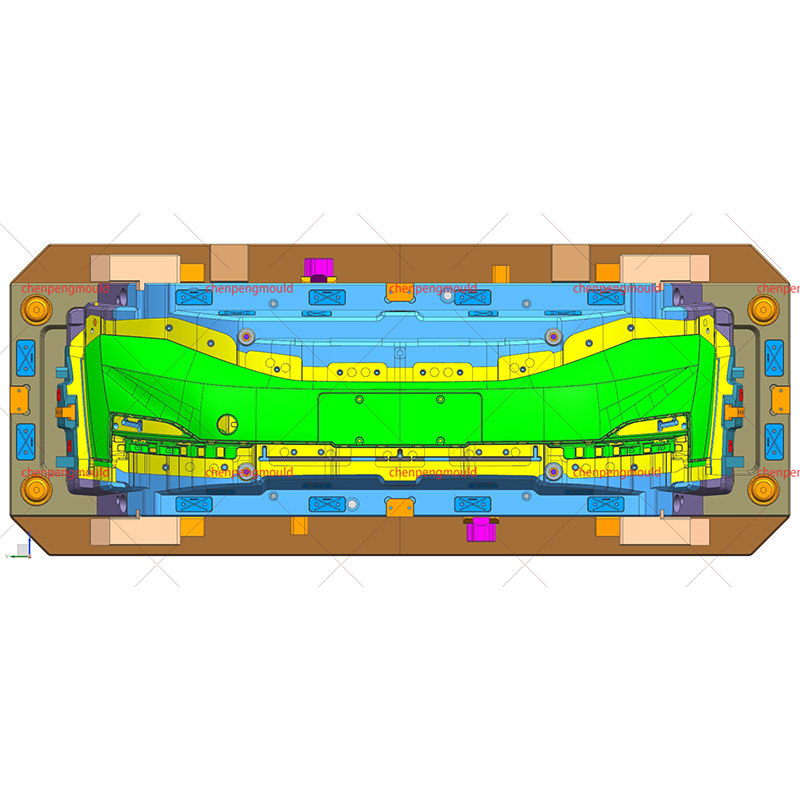

Mould Name Skoda Kamiq Bumper Mould

Material PP+EPDM(Contraction: 1, 5%)

Bumper Size 1800*510*460mm

Steel For Cavity &. Core P20

Mould Base C45

NOs. of Cavity 1*1

Injection System Yudo 5 direct injection gates

Ejection System Ejector pins, angle lifters

Mould Standard OEM/HASCO

Mould Estimated Size 2200 x 950 x 1000mm

Mould Weight 12500KG

Injection Machine Size 1850T

Mould Lifetime 5years